Synthetic Fabrics

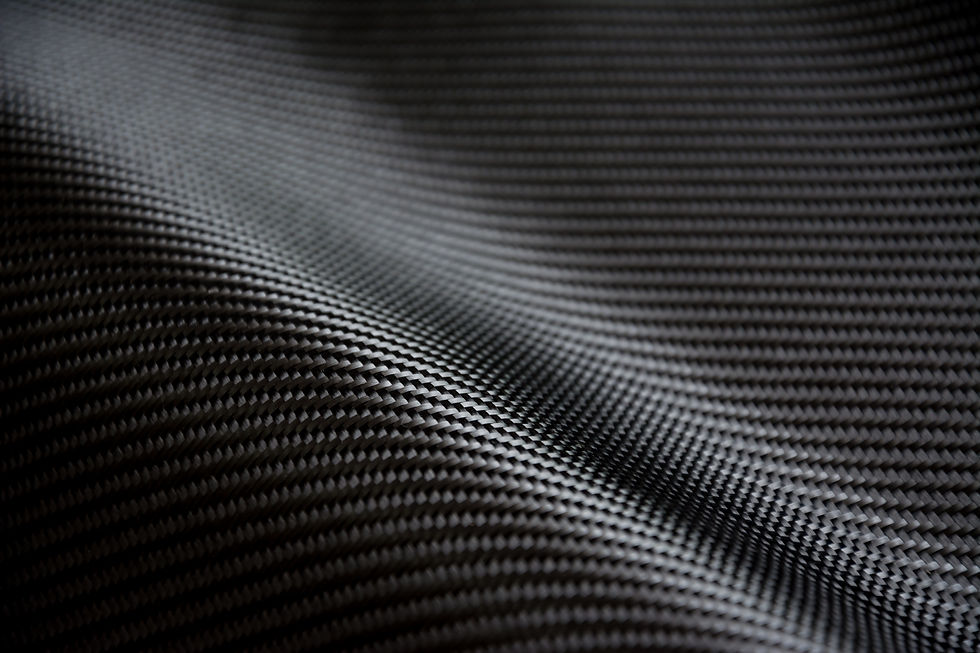

Carbon Fiber Fabric

Carbon fiber is a lightweight, durable fiber used in advanced composites. Made of thin, strong crystalline graphite materials, carbon fiber has a wide arrange of applications due to its ability to be formed at various densities, allowing it to form into limitless shapes and sizes. Used primarily in the automotive industry because of its strength and damage tolerance, carbon fibres are also being used in variety fields such as Aero space, Drones, Tubes and pipes, sheet, Wind turbine blades, Construction reinforcement etc.

Properties:

-

High strength and light in weight.

-

Easy mouldability.

-

Corrosive resistant.

-

Chemical resistant.

Packing:

-

The woven CF fabric is wound around a cardboard cylinder and wrapped with the polyethene cover.

-

Then the full roll will be placed inside the card board box.

-

For transportation multiple rolls will be placed on the pallet and fastened tightly.

Yarn Grade

T300

GSM

200

Yarn Count

3K

Weave Type

Plain

Yarn Grade

T300

GSM

200

Yarn Count

3K

Weave Type

Twill

Yarn Grade

T300

GSM

400

Yarn Count

6K

Weave Type

Plain

Yarn Grade

T300

GSM

400

Yarn Count

6K

Weave Type

Twill

Yarn Grade

T300

GSM

600

Yarn Count

12K

Weave Type

Plain

Yarn Grade

T300

GSM

600

Yarn Count

12K

Weave Type

Twill

Please contact us for different GSMs and Weavings patterns.

Our machines are capable of weaving GSM ranging from 100 -1000 and width ranging from 0.3 mtr to 1.5 mtr.

Glass Fiber Fabrics

E Glass Fiber Glass Woven roving is a bidirectional fabric made by interweaving fiberglass direct rovings. This is one of the strongest textile fibres, having greater specific tensile strength than steel wire of the same diameter, at a lower weight. It is a high-performance reinforcement and widely used in processes such as in hand lay-up, moulding, and pultrusion. Some of the applications are Automobile parts, Mechanical parts, Swimming pools, Boats, jets, surfing boards, chemical tanks, Insulated door, Enclosures, wind turbine blades etc,

Woven roving is compatible with many resins, such as polyester, vinyl ester and epoxy resins.

Properties:

-

Warp and weft roving aligned in a parallel and flat manner, resulting in uniform tension and a very little twist

-

Good moldability, fast and complete wet in resins, resulting in high productivity.

-

Good transparency and high strength of composite products

-

Warp and weft roving aligned in a parallel and flat manner resulting in uniform tension.

-

Excellent mechanical properties.

-

Good wet-out in resins.

-

Our standard width is 1mtr, however custom width ranging from 0.3 mtr to 1.5 mtr is possible with our machines

-

Both Plain and Twill weave is possible.

Packing:

-

The woven roving is wound around a card board cylinder and wrapped with the polyethene cover.

-

Then the full roll will be placed inside the card board box.

-

For transportation multiple rolls will be placed on the pallet and fastened tightly.

GSM

200

Tex

180

Weave Type

Plain & Twill

GSM

300

Tex

300

Weave Type

Plain & Twill

GSM

400

Tex

600

Weave Type

Plain & Twill

GSM

500

Tex

900

Weave Type

Plain & Twill

GSM

600

Tex

1200

Weave Type

Plain & Twill

GSM

800

Tex

2400

Weave Type

Plain & Twill

.png)